Beltrami and Hubbard counties planned pavement rehabilitation on a shared road, presenting a unique opportunity to directly compare two stabilizers: engineered emulsion and Base One®, a proprietary mix. After work was completed, both road segments met design values for pavement strength, according to an LRRB-funded study.

Local transportation agencies rely on stabilized full-depth reclamation (SFDR) as a pavement rehabilitation strategy. The process creates a supporting recycled road base layer by pulverizing the existing pavement, adding a stabilizer, compacting the layer, and overlaying with a surface layer of asphalt.

Previous LRRB research found that SFDR produced a stronger base than regular aggregate of the same thickness. While the LRRB had sponsored additional research on full-depth reclamation, different stabilizers had not been directly compared.

This project found that in general, both stabilizing products resulted in pavements that exceeded their 10-ton design value. After one year of service, both segments were in visibly good condition despite some low-severity transverse cracking. The Hubbard County segment, treated with Base One, had more than five times as many cracks as the Beltrami County segment, which was treated with engineered emulsion.

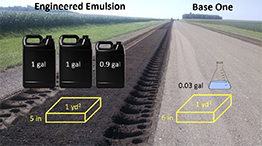

The recommended application rate for the engineered emulsion was 2.9 gallons per square yard; for Base One, 0.03 gallon per square yard. Comparing the product costs, the engineered emulsion ($88,391 per mile) was eight times the cost of Base One ($10,625 per mile). Total construction costs for the Beltrami segment, which required an extra mix design step and different equipment, were about 39 percent higher than the Hubbard segment.

Learn more:

- Evaluation of SFDR Stabilizing Products (LRRB/MnDOT, 2022)